Many of our customers find themselves using older “conventional” mixing equipment in their batching processes simply because that’s what everyone had used over the years. High pressure homogenizers are a classic example of this, particularly in the production of intermediate food and beverage bases and emulsions.

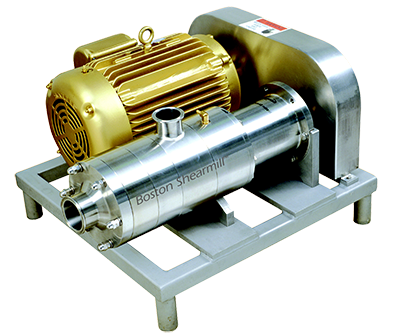

Admix Boston Shearmill (BSM) produces shelf stable bases and emulsions while using half the energy, half the water, and 10% of the maintenance expense of a conventional high pressure homogenizer.

Initial testing at our pilot plant, followed by in-plant trials with our BSM have allowed many our clients to eliminate the homogenizer, along with its high cost of ownership, from their processes.

Initial testing at our pilot plant, followed by in-plant trials with our BSM have allowed many our clients to eliminate the homogenizer, along with its high cost of ownership, from their processes.

The BSM delivered the functionality and texture to their products they thought only achievable with high pressure homogenizers. And at flow rates up to 250 gpm, batch times are drastically reduced.

If you are making emulsions like Natural Cloud, Natural Orange, or Neutral Cloud give us a call and we’ll show you how others are achieving Surface Whtd Means of 0.242, 0.948, and 0.406 micron with a single pass through the BSM.