How The Rotosolver Disperser Works

Overview | Specifications | Options

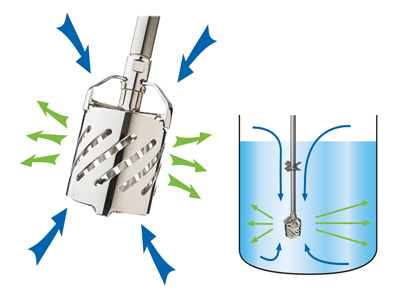

The Rotosolver combines the shearing capabilities of a high speed toothed rotor and a slotted stator with the additional advantage of high flow / circulation from the dual rotor blades. This unique mixing head design of the disperser provides a four-stage mixing action:

The Rotosolver combines the shearing capabilities of a high speed toothed rotor and a slotted stator with the additional advantage of high flow / circulation from the dual rotor blades. This unique mixing head design of the disperser provides a four-stage mixing action:

- Product flow is drawn into the mixing head from above and below. As flow is drawn in, materials and powders pulled down from the top (typically the toughest to disperse) are immediately exposed to two additional mechanical shear zones and one shear zone from the bottom. These materials are then immediately mechanically ripped by the teeth on the rotor’s discharge at the top and bottom of the stator.

- The two high velocity, countercurrent streams converge within the stator causing high turbulence and hydraulic shear, without momentum loss from obstructions within the stator.

- Centrifugal pressure forces material to the periphery of the stator where it is subjected to further mechanical shear from the sharpened edges of the expanded slots in the stator.

- The high velocity radial discharge combines with slower moving tank flow for additional hydraulic shear and circulation.